Technical

AD 530: Countersunk head bolts

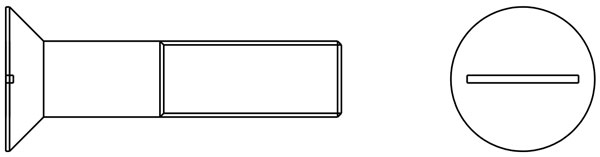

Countersunk head bolts may be manufactured with a slot (for a screwdriver), see Fig. 1, or a hexagonal socket (for an allen key driver), see Fig. 2. This AD is to advise that countersunk bolts with a hexagonal socket may have reduced tensile resistance due to the reduced section at the head-to-shank location and should be used with care.

This note only applies to non-preloaded countersunk head bolts. Countersunk head bolts used as a preloaded assembly are manufactured to BS EN 14399-7, have a screwdriver type slot and have full loadability. Preloaded countersunk head bolts to BS EN 14399-7 may be used without preloading.

Requirements for non-preloaded countersunk head bolts are specified in BS 4933. The Note to Table 8 of BS 4933:2010 permits the forming of a feature to prevent rotation at the choice of the manufacturer. The note goes on to state that the feature should not reduce the “loadability” of the fixing when subject to an axial tensile force. The note provides a forward reference to BS EN ISO 898 for further guidance.

BCSA produce a Model specification for the purchase of structural bolting assemblies and holding down bolts which currently (14th edition) requires that countersunk bolt assemblies subject to tensile loads, or combined shear and tensile loads should only be supplied with a screwdriver slot, unless an alternative can be demonstrated to not adversely affect the bolt loadability.

BS EN ISO 898-1:2013 specifies mechanical properties for fasteners in carbon and alloy steel. The scope recognises that certain fasteners might not fulfil the tensile requirements because of the geometry of the heads, including those with a countersunk head. Clause 8.2 of BS EN ISO 898-1:2013 identifies the geometric reasons why a fixing might have reduced loadability, including a countersunk head with an internal driving feature (a hexagonal socket).

Despite the possible inference in the scope that reduced loadability fasteners are not covered, BS EN ISO 898-1:2013 specifies testing requirements for reduced loadability fasteners in Table 10, requiring that (among other things) the fastener achieves at least the minimum ultimate tensile load in the product standard.

The product standard for countersunk fasteners with socket heads is BS EN ISO 10642:2019, including hexagonal socket countersunk head screws with reduced loadability, up to M20. The minimum ultimate resistance is given as 80% of the value for fixings with full loadability.

Clause 5 of BS EN ISO 898-1:2013 requires fasteners with reduced loadability to be marked with a zero preceding the normal property class designation. A reduced loadability property class 8.8 fastener becomes 08.8.

Countersunk bolts with a hexagonal socket head may also be specified to DIN 7991. This is a withdrawn standard and does not specify a loadability test. It is recommended that countersunk head bolts are not specified to this standard.

BCSA’s Model specification for the purchase of structural bolting assemblies will be reviewed later this year (to be issued as 15th edition) to omit a reference to DIN 7991 and to reflect the advice in this AD about the use of bolts with reduced loadability.

Design tension resistance of countersunk head bolts with a hexagon socket

If countersunk head bolts with a hexagonal socket are to be used, their design tension resistance should be reduced by applying a 0.8 factor to the calculated resistance given in BS EN 1993-1-8:2005. It should be noted that the values given in the “Blue Book” and similar resources are applicable only to countersunk heads with a screwdriver slot.

In addition when specifying or using countersunk heads with a hexagonal socket:

- The fixings should be specified in accordance with BS EN ISO 10642:2019,

- The mechanical properties should meet the requirements of BS EN ISO 898-1:2013,

- The fixing should be correctly marked with a zero preceding the normal property class.

It should be clear that if a joint design using countersunk head bolts has been based on the design resistances calculated in accordance with Table 3.4 of BS EN 1993-1-8:2005, only countersunk head bolts with a screwdriver slot should be used, unless the design is verified for reduced loadability socket head fasteners.

If a design is completed using the reduced value of tensile resistance, countersunk head bolts to either BS 4933:2010 (with slots) or BS EN ISO 10642:2019 (with sockets) may be used.

Contact: David Brown

Telephone: 01344 636555

Email: advisory@steel-sci.com